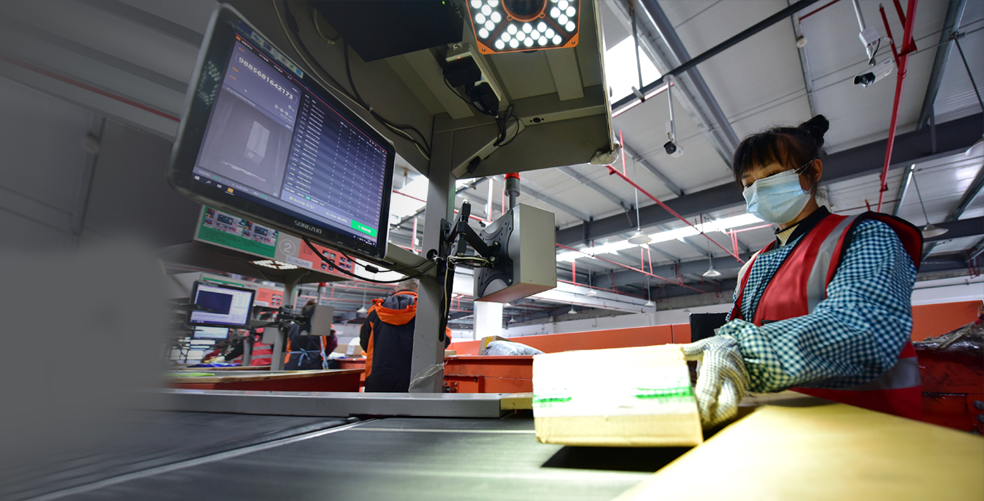

With Depot Master DWS systems widespread used for around of the world, our expert technical team has accumulated extensive experience and technical expertise in parcels and mails solutions to assist you in achieving your goals.

The Depot Master system relies on strong software development and hardware control capabilities,

It seamlessly integrates with any external system and is even better than what you think

Static DWS A

Capacity: 1800-2000 pcs / h

Static DWS A is the most cost-effective products, with industrial camera, automatic scanning, instead of handheld PDA scanning, automatic weighing and volume measurement, free hands. Equipped with movable casters that can be freely pushed to adapt to different working environments, seamless integrating with any system, real-time data upload, no debugging required, just plug and play. Can fast and dynamic recognition of bar code information of varied parcels, automatically complete the online information collection, entry and saving, high efficiency, high recognition accuracy and affordable cost.

It's the best helper for parcels handling in your e-commerce or warehousing business.

Measuring speed: less than 1 second per product

Minimum: W x D x H

Min Bar-code reading width: 10mil

Maximum: W x D x H

Measuring Accuracy:

Minimum: 0.005kg / 0.011 lbs

Maximum:50kg / 110 lbs

Weight Accuracy: ≤ 0.002kg / 0.0044 lbs

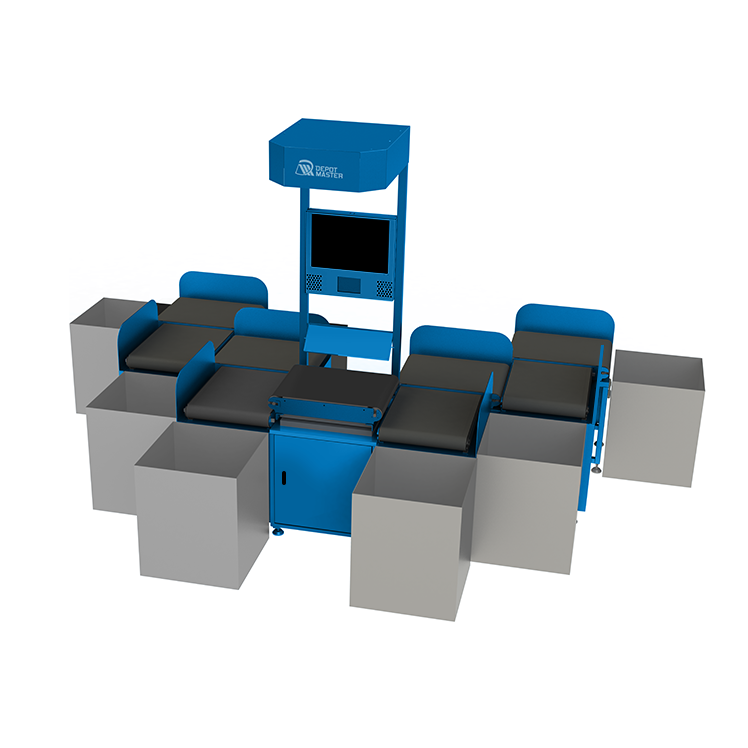

Static DWS B

Two Directions Sorting System

Capacity: 2000-3000 pcs / h

Static DWS B is an intelligent product that can sort left and right, its left and right sides can be connected to the conveyor line, able to be used for automated sorting line or for independent work, can fast and dynamically identify the bar-code information of various parcels, and automatically complete the on-line information collection, entry, and preservation, with high efficiency and high recognition accuracy.

Measuring speed: less than 1 second per product

Minimum: W x D x H

Min Bar-code reading width: 10mil

Maximum: W x D x H

Measuring Accuracy:

Minimum: 0.005kg / 0.011 lbs

Maximum:50kg / 110 lbs

Weight Accuracy: ≤ 0.002kg / 0.0044 lbs

Static DWS C

Multiple Directions Sorting System

Capacity: 2000-3000 pcs / h

Static DWS C accurately sorts parcels to their designated locations through precise calculation and recognition technology, it not only greatly shortens the time for order fulfillment, but also avoids return shipments and returns due to manual sorting errors. It not only sorts packages, and also has volumetric measurement, weighing and code scanning functions.

Static DWS C is one of the most cost-effective and efficient sorting solutions for the efficient handling of parcels in efficient express, logistics, e-commerce and warehousing environments. It can also be expanded to 6, 8 and many Directions according to the amount of parcels to be handled.

Measuring speed: less than 1 second per product

Minimum: W x D x H

Min Bar-code reading width: 10mil

Maximum: W x D x H

Measuring Accuracy:

Minimum: 0.005kg / 0.011 lbs

Maximum:50kg / 110 lbs

Weight Accuracy: ≤ 0.002kg / 0.0044 lbs

Dynamic DWS A

Capacity: 2000-3000 pcs / h

The Dynamic DWS is an intelligent logistics system with a modular design that combines automatic weighing, automatic code reading and automatic volume measurement. Using 3D imaging technology to scan bar-codes, supplemented by AI intelligent algorithms to synchronously parse the bar-codes, measure the dimensions of the goods in real time quickly and accurately and automatically calculate the volume,and Integration with Dynamic scale for Simultaneous weighing, afterwards, the data will be integrated and sent to the user's own system or designated path, and the original express sheet and data information will be saved so that realize integration of code reading, dimensioning, data collection and tracking & tracing.

Depot Master Dynamic DWS A system is a cost-effective parcel handling system that offers a 500% increase in efficiency compared to manual methods, a fast return on investment, easy installation, integration with any system, stand-alone operation or connection to a conveyor line according to the customer's requirements.

Measuring speed: less than 1 second per product

Minimum: W x D x H

Min Bar-code reading width: 10mil

Maximum: W x D x H

Measuring Accuracy:

Minimum: 0.005kg / 0.011 lbs

Maximum:50kg / 110 lbs

Weight Accuracy: ≤ 0.002kg / 0.0044 lbs

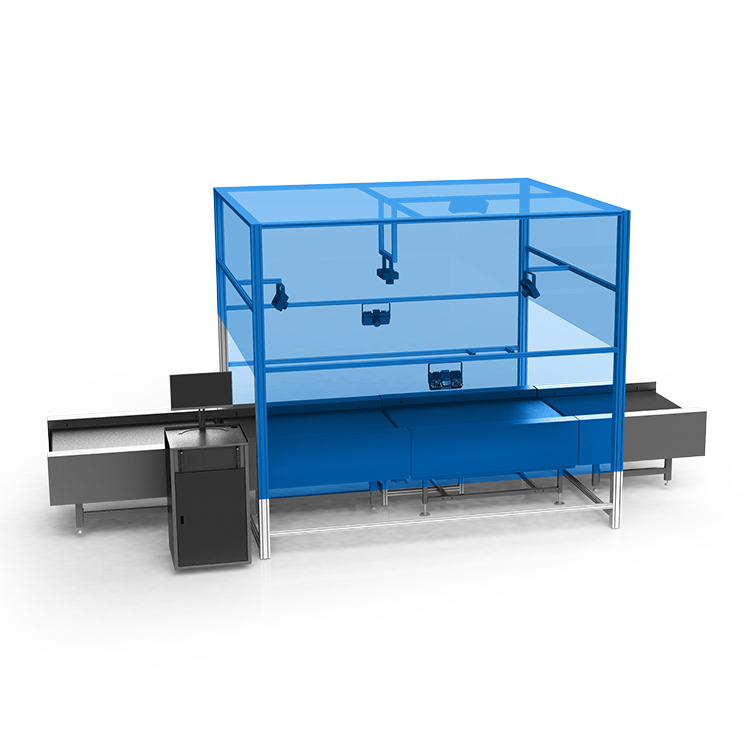

Dynamic DWS Six-Side Scanning System

Capacity: 3000-5000 pcs / h

Measurement Technology:3D binocular vision technology

Measurement range:0.1KG-60KG

Volume accuracy:Plus or minus 10mm

Measuring range:120*80*80(cm)

Weight accuracy:1/3000

Automatic scanning:Intelligent/industrial camera reading

Scanning depth of field:60cm

Scanning recognition rate:99.9%

Conveyor line height above ground:70cm (Standard)

Conveyor width:120cm (standard)

Throughput:3000-5000 pcs per hour

Line speed:50-100m/min

Power supply:Single phase 220V 50~60HZ

Peripheral accessories:Carrying table (optional parts)

Data interface:Customized development of docking program on demand

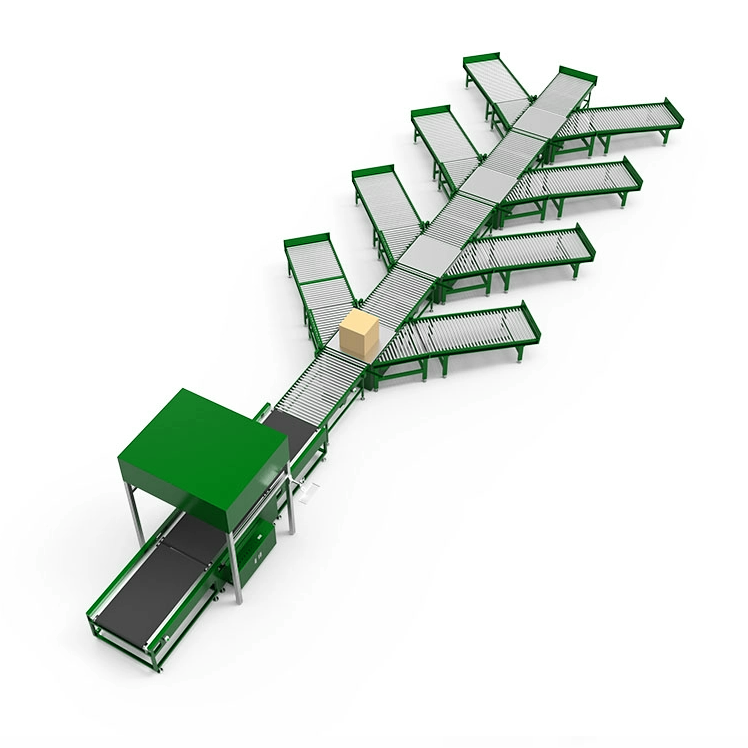

Dynamic DWS B

Capacity: 2500-4000 pcs / h

Dynamic DWS B system is a Multi-functional automated warehousing system with Sorting, Conveying, Volume Measurement, Weighing and Barcode Reading capabilities, Swivel Wheel Sorters and Roller or Belt Conveyor Lines are connected with DWS system to facilitates the picking and conveying of larger parcels to a number of different destinations.

Functions: Volumetric Measurement, Weighing, Barcode Reading, Sorting and Conveying.

Measuring speed: less than 1 second per product

Minimum: W x D x H

Min Bar-code reading width: 10mil

Maximum: W x D x H

Measuring Accuracy:

Minimum: 0.005kg / 0.011 lbs

Maximum:50kg / 110 lbs

Weight Accuracy: ≤ 0.002kg / 0.0044 lbs

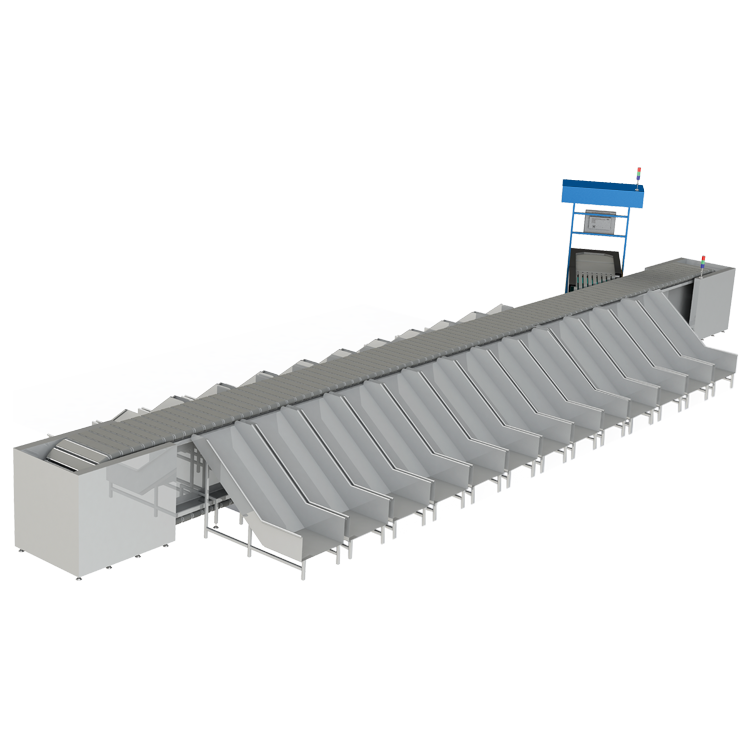

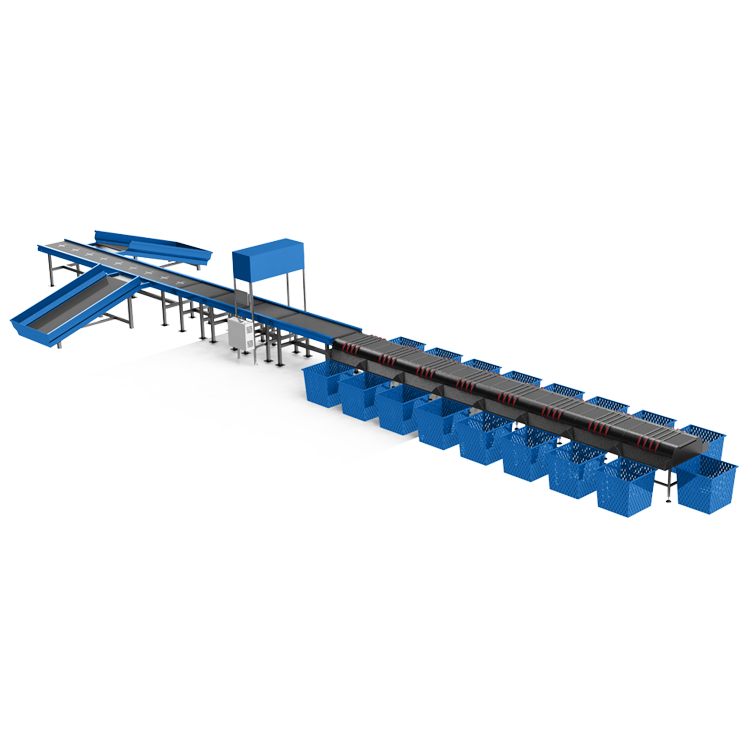

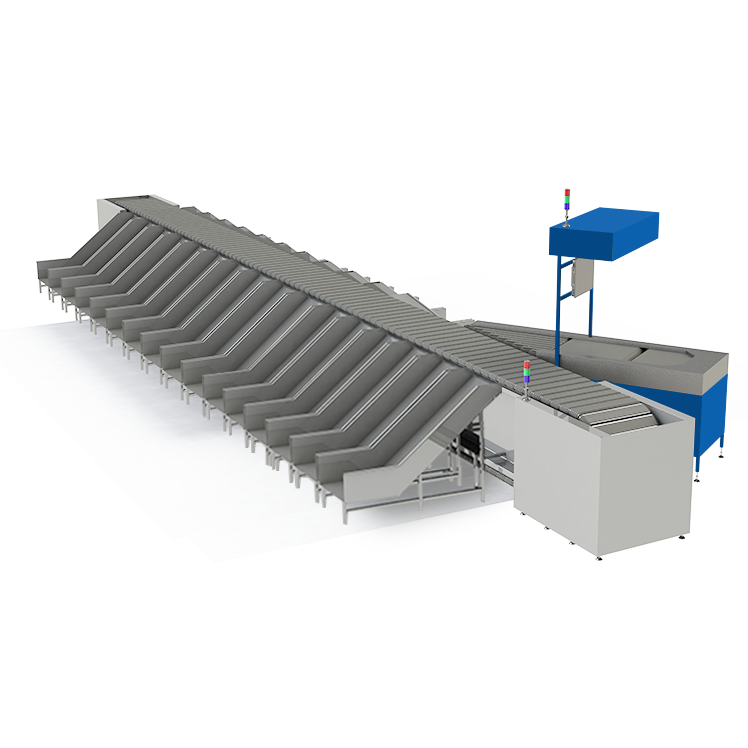

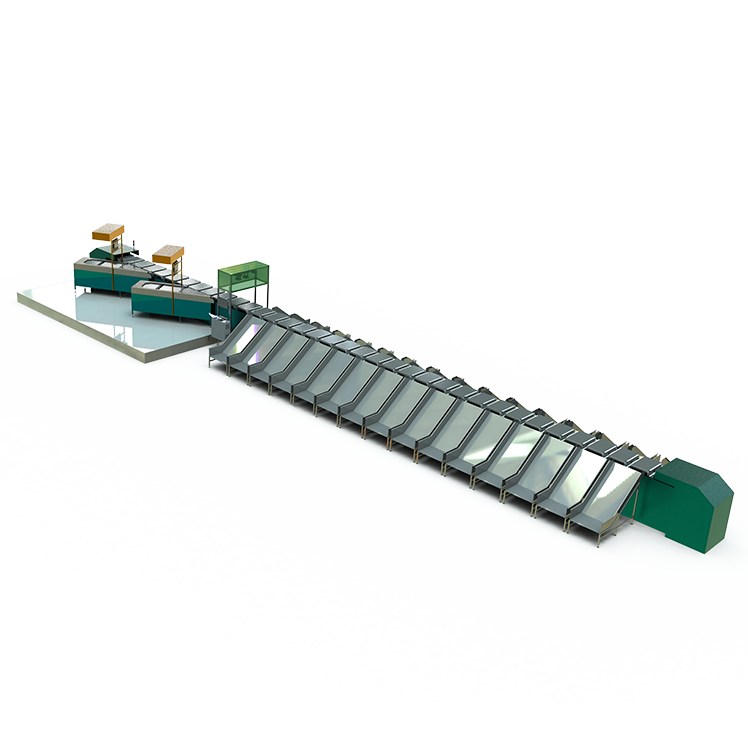

High-speed Strip-belt Modular Sorter

Capacity: 3000-5000 pcs / h

High-speed strip-belt modular sorter is a highly efficient and accurate automatic sorting system for parcels, widely used for logistics, warehousing, e-commerce and other fields. The high-speed strip-belt modular sorter is capable of sorting many types of parcels and excels in high efficiency, high precision, high flexibility,flexible expansion according to business development, intelligence and higher space utilization. It can quickly sort out different items according to the size, shape and other characteristics of the products to improve production and logistics efficiency. Adopting modular split design, the upper part of the main machine and the lower part of the legs can be separated, and the height of the legs can be customized. The electric control box is hidden at the bottom of the mainframe and adopts pull-out design for easy maintenance.

Application Scenario: Widely used for logistics, warehousing, e-commerce and other fields.

Power per unit:600w

Sorting Capacity:3000-5000pcs/h

Package Size:L10cm*W10cm*H10cm-L50cm*W50cm*H50cm

Weight:0-30KG

Unit Module Specification:L80cm*W68cm*H86cm (Special oversized and oversized size can be customized)

Noise level:75dB

Equipment Innovations:The running direction of parcels is driven by synchronous belt to prevent parcels from jumping, chasing, slipping and running off, etc. It can sort various types and sizes of parcels.

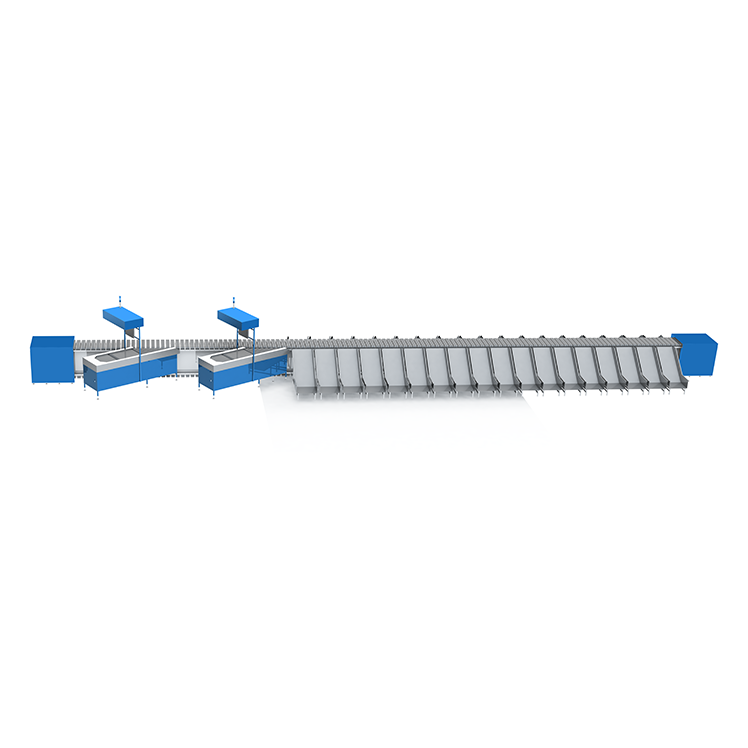

High-speed Narrow-belt Sorter

Capacity: 7000-9000 pcs / h

Parcel Sorting Type:Cartons, parcels, flexible packages,partially shaped parts

Trolley Pitch:20cm

Parcel Sorting Specification:Min: L10cm*W5cm*H0.2cm / Max: L120cm*W100cm*L80cm

Trolley Load Weight:Min: 10g Max: 60kg

Parcel feeding method:Manual, semi-automatic, automatic

Driving method:Linear motor, chain driven

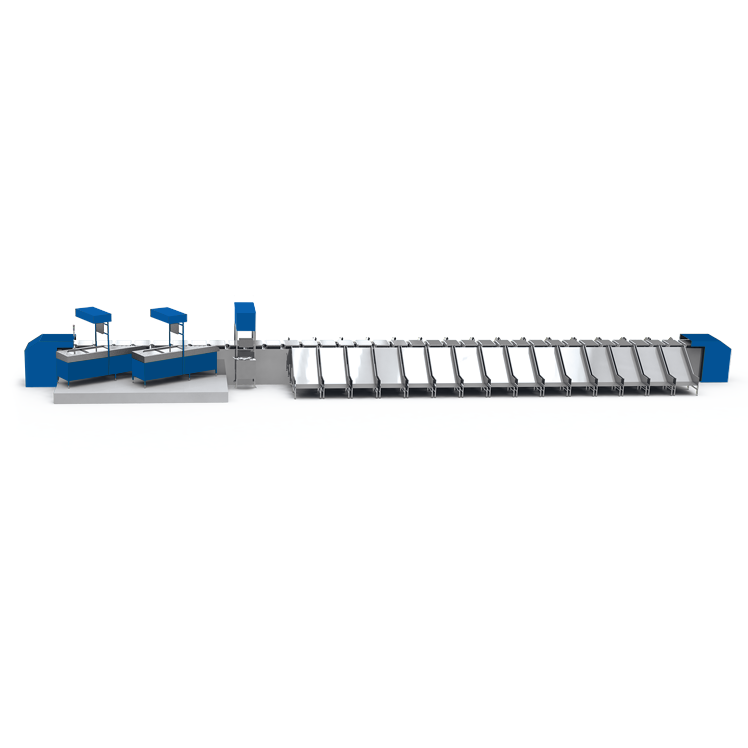

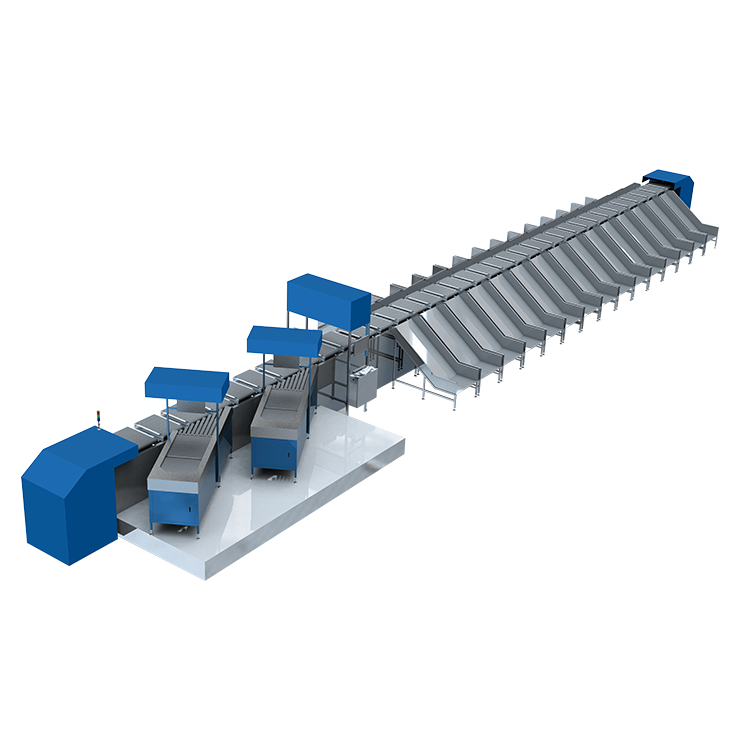

Linear Cross Belt Sorter

Capacity: 10800-14400 pcs / h

Maximum sorting capacity (pieces/hour):10,800 PPH

Running Speed (m/s):<1.5 m/s

Sorting weight range:Min. 5g, Max. 35kg

Sorting size range (cm):Min. 10Lx10Wx0.5H, Max. 60Lx35Wx40H

Trolley size (cm):42.6x70

Trolley spacing (cm):50

Trolley sorting drive (optional):Drum motor or servo motor

Trolley Sorting Power Pickup (optional):Sliding contact (carbon brush) or contactless (high frequency induction)

Trolley Loop Run Drive:Linear motor, (electromagnetic drive)

Sorting Loop Run Power:DC 48 Volt

Sorting system noise level:<72 dB

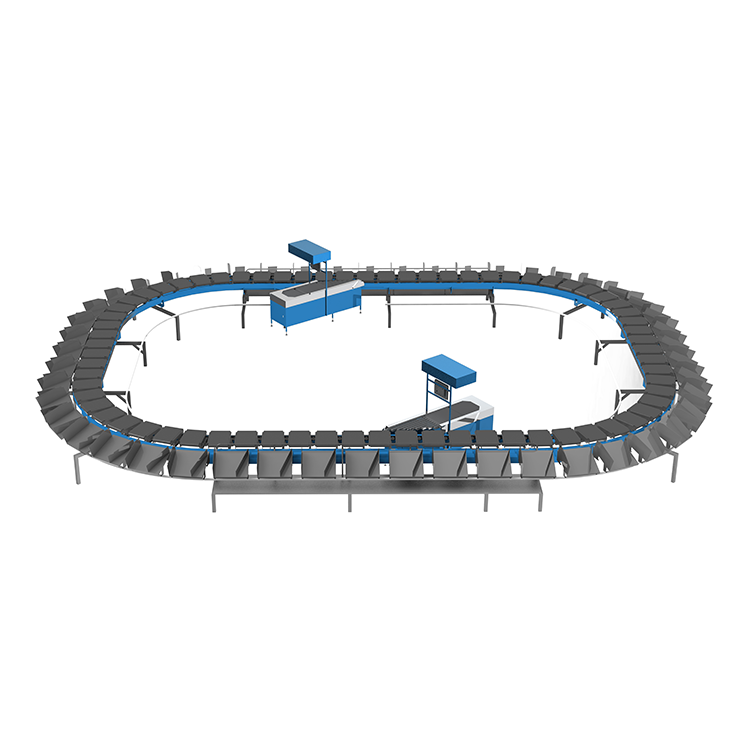

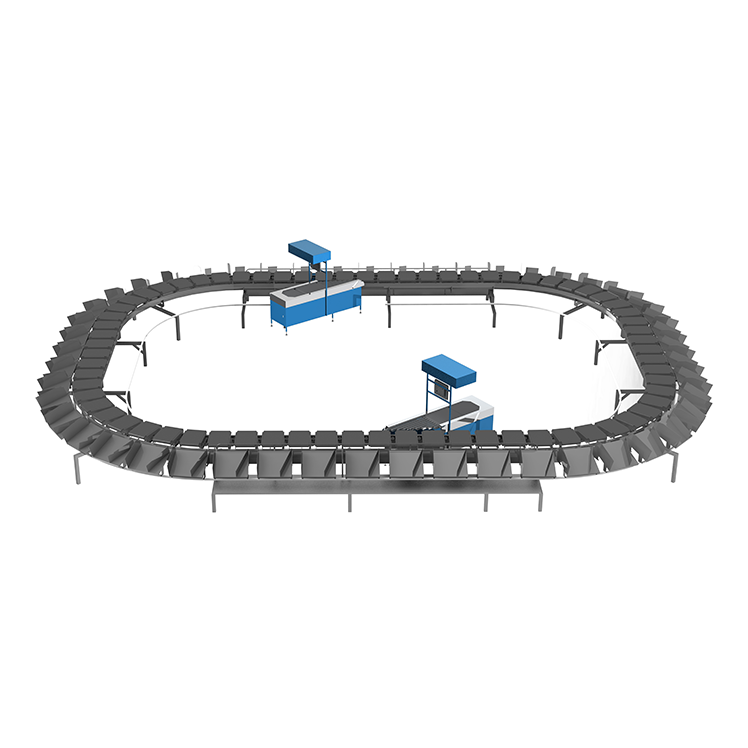

Circular Cross Belt Sorter

Capacity: 9000-35000 pcs / h

Barcode Reader:2000W Smart Camera

Application Software:DM code reading software

Table Size:Customized

Volume Measurement Accuracy:Optional

Maximum Package Size:40X50X40cm(LxWxH)

Loop working height:75cm

Trolley spacing:50cm

Trolley size:40cmX70cm

Handling volume:9000votes/hour-35,000votes/hour

Trolley Safe Load:20KG

Sorting compartment spacing:75cm

Operating Temperature:0-35°C

Power supply:380V

Software Interface:http, tcp,485

Operation Mode:Manual loading, weighing table loading

Weighing Mode:Manual / Automatic

Picture acquisition:yes

Remote diagnostics:yes

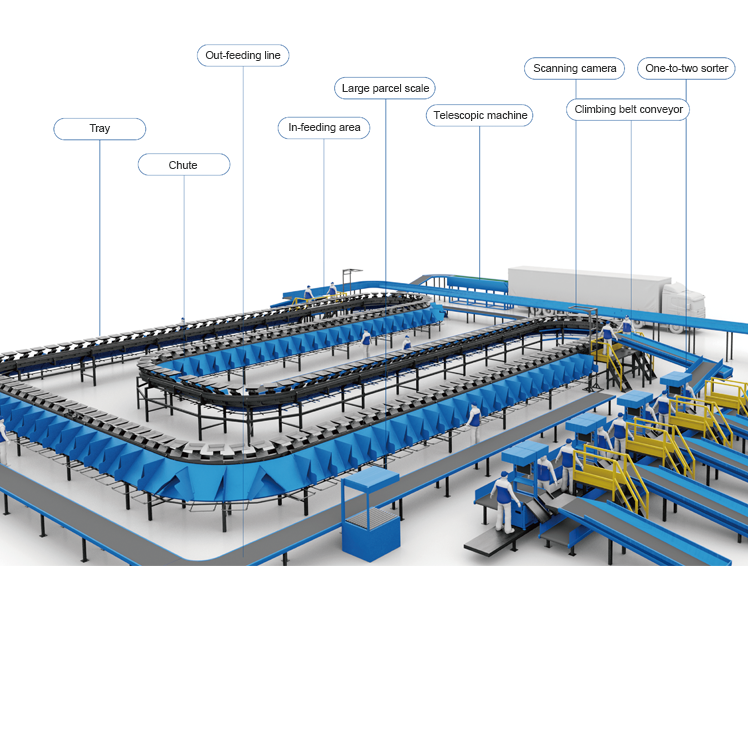

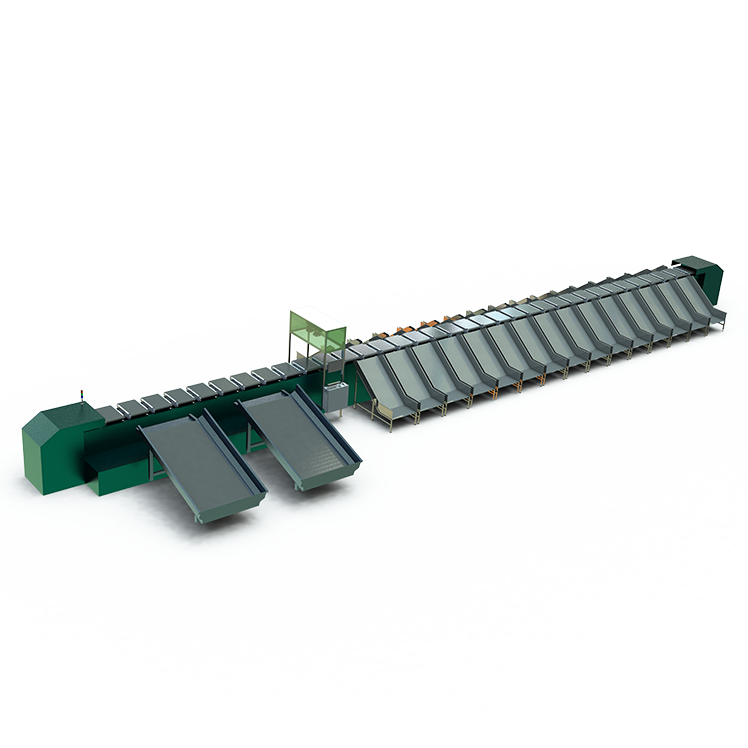

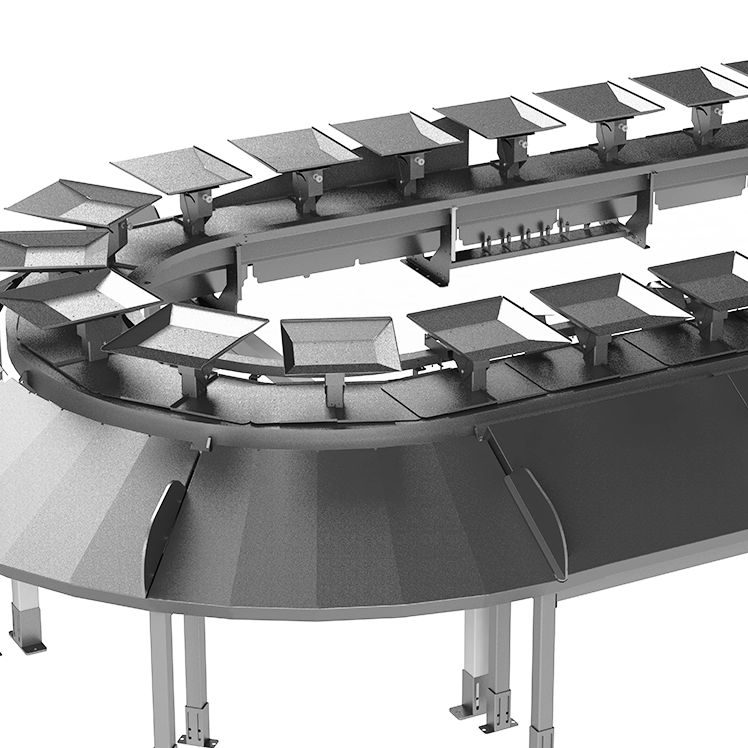

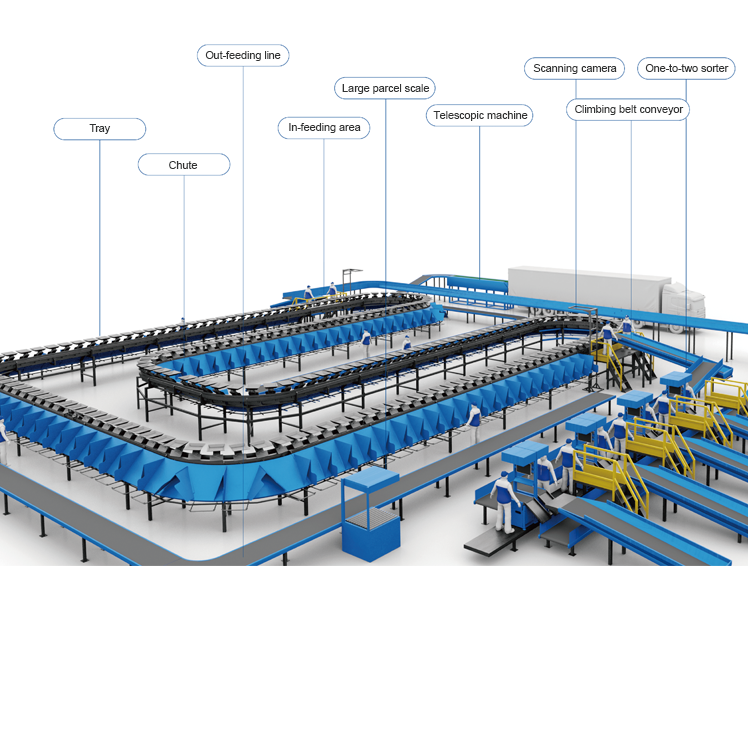

Circular Tilt-tray Sorter

Capacity: 8500-34000 pcs / h

Equip. height (M):3.4/4.5

Equip. width (M): Customized

Tray height (M):2/3.1

Tray size (CM):50*43

Parcel size (CM):45*40*30

In-feeding area:1~4

Number of parcel placing staffs:4~16

Grid width (M):0.75

Carrying capacity (KG): ≤5

Handling efficiency (single zone):8500 votes/hour

Handling efficiency (dual zone):12000ticket/hour

Power supply:380V 50HZ

Motor power (Kw):2.2XN

Code reading recognition rate is:99%

Tray running speed is:1.3m/s~1.5m/s